Mukushanda kwemichina yeflexographic, kuoma kweinki zvishoma nezvishoma kunokonzera kusviba kwave kuri dambudziko rinogara riripo kumakambani ekudhinda. Izvi hazvingokanganisi kunaka kwekudhinda chete uye zvinowedzera marara asiwo zvinoderedza kushanda zvakanaka kwekugadzira uye zvinogona kutononotsa nguva yekutumira. Dambudziko iri rinogona kugadziriswa sei zvinobudirira? Isu tinopa mhinduro yakazara inosanganisira kusarudzwa kweinki, kugadzirisa mashandiro, kuvandudza michina, uye kudzora nharaunda kuti tikubatsire kubvisa kusviba uye kuwana kugadzirwa kwekudhinda kwakasimba uye kwakanaka.

Mukushanda kwemichina yeflexographic, kuoma kweinki zvishoma nezvishoma kunokonzera kusviba kwave kuri dambudziko rinogara riripo kumakambani ekudhinda. Izvi hazvingokanganisi kunaka kwekudhinda chete uye zvinowedzera marara asiwo zvinoderedza kushanda zvakanaka kwekugadzira uye zvinogona kutononotsa nguva yekutumira. Dambudziko iri rinogona kugadziriswa sei zvinobudirira? Isu tinopa mhinduro yakazara inosanganisira kusarudzwa kweinki, kugadzirisa mashandiro, kuvandudza michina, uye kudzora nharaunda kuti tikubatsire kubvisa kusviba uye kuwana kugadzirwa kwekudhinda kwakasimba uye kwakanaka.

● Kusarudzwa kweInki & Kugadzirisa Fomura - Kugadzirisa Matambudziko Ekuomesa Panobva

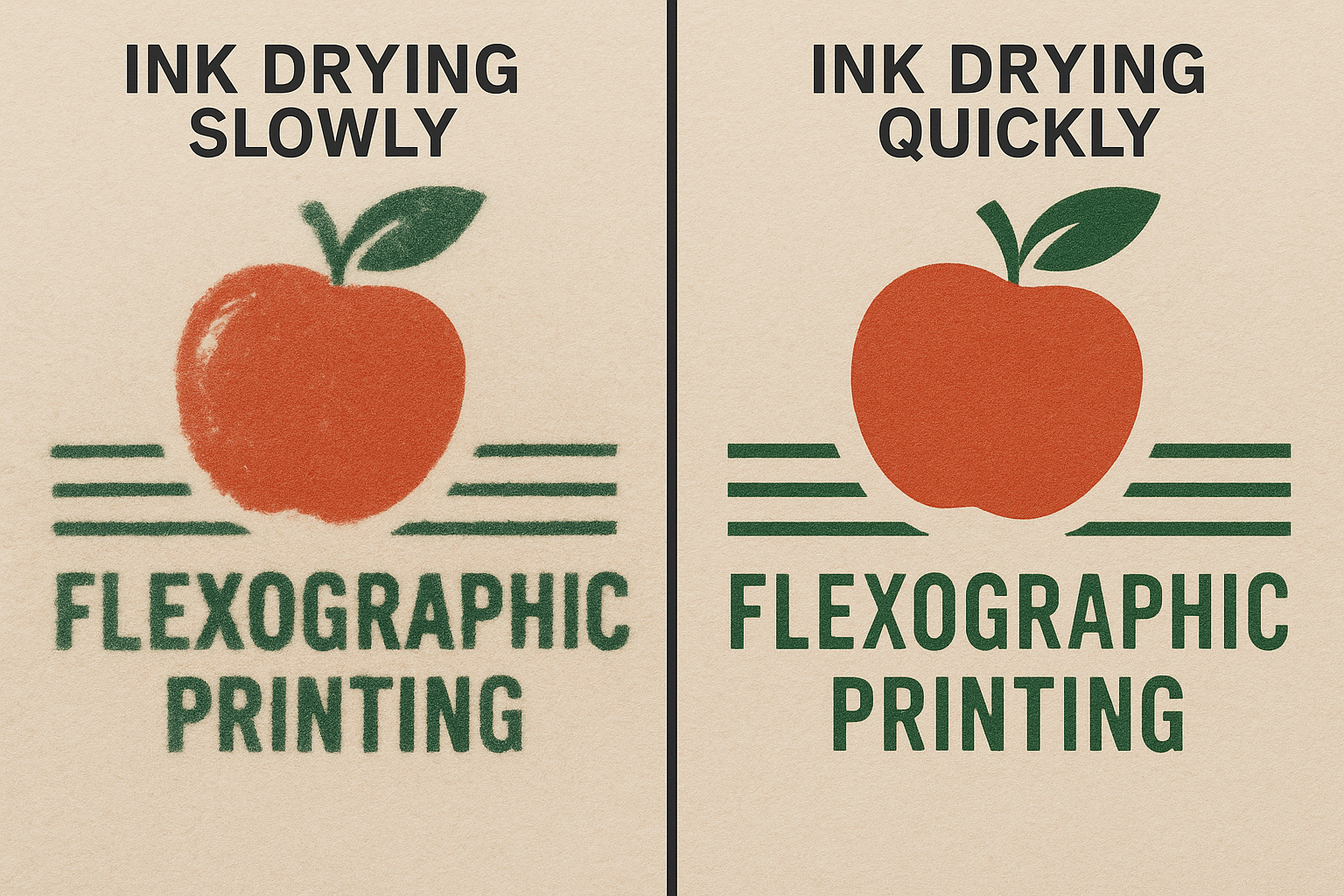

Kune michina yekudhinda yeflexo, kusarudza uye kugadzira inki kwakakosha pakugadzirisa matambudziko ekuomesa. Tinokurudzira inki dzinoomesa nekukurumidza, dzakadai seinki dzinonyungudutsa dzine maformula ane high-volatility formulations kana inki dzinonyungudutsa mvura dzine accelerators yekuomesa. Kuti iome nekukurumidza, inki dzeUV dzakabatana ne ultraviolet curing systems ndiyo sarudzo yakanakisisa. Kugadzirisa solvent ratios—senge kuwedzera ethanol kana ethyl acetate—kunogona kuwedzera mashandiro ekuomesa uku uchichengetedza inki yakagadzikana. Pamusoro pezvo, kusarudza zvinowedzerwa zvekuomesa zvakakodzera (semuenzaniso, cobalt/manganese driers ye oxidative drying inks kana specialized penetrants ye substrates dzinonyungudutsa) kunoita kuti pave nemigumisiro yakanaka.

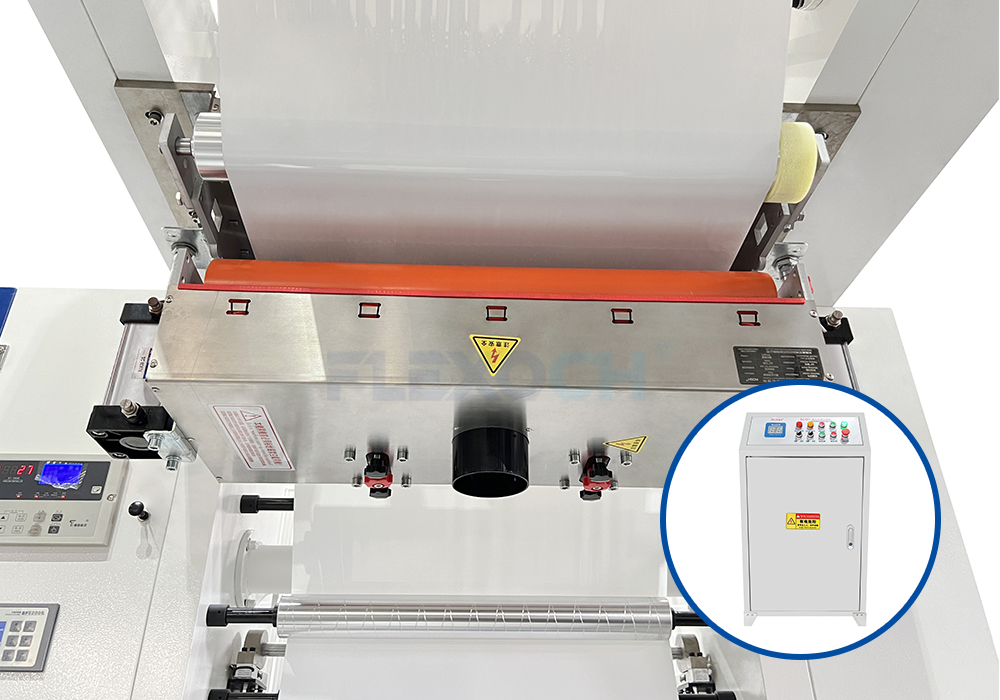

● Kuvandudzwa kweSisitimu Yekuomesa - Kuvandudza Kushanda Zvakanaka

Kushanda kwemasystem ekuomesa mumuchina we flexo printing kunokanganisa mhedzisiro. Gara uchiongorora ma dryer kuti uve nechokwadi chekuti tembiricha yakakodzera (50–80°C ye inki dzinonyungudutsa, yakaderera zvishoma yemvura) uye mhepo isina kuvharwa. Pakushandisa kwakaoma, wedzera kuomesa kwe infrared kuti ushande zvakanaka kana UV kuti uome ipapo ipapo. Mayuniti ekuomesa nemhepo inotonhora anonyanya kubatsira kumafirimu asinganwi inki kudzivirira kunyorovesa zvakare.

● Kugadzirisa Maitiro Ekudhinda - Kugadzirisa Maparamita Ekugadzira

Mumichina yekudhinda ine flexographic, kugadzirisa maparamita ekugadzira kunovandudza kushanda zvakanaka kwekuomesa. Kudzora kumhanya kwekudhinda kwakakosha—kumhanya kwakanyanya kunodzivirira kuomesa kwakakodzera chiteshi chekudhinda chinotevera chisati chasvika. Gadzirisa kumhanya zvichienderana nehunhu hweinki uye kugona kweomesa. Kugadzirisa ukobvu hwefirimu reinki kuburikidza nekusarudza kwakakodzera anilox roller uye huwandu hweinki kunodzivirira kuwanda kwakanyanya. Pakudhinda kwemavara akawanda, kuwedzera nzvimbo yechiteshi kana kuwedzera maomesa pakati pechiteshi kunowedzera nguva yekuomesa.

● Kugadziriswa Kwenzvimbo Nenzvimbo - Zvinhu Zvinokosha Zvekunze

Mamiriro ekunze mukushanda kweprinta yeflexo anokanganisa zvakanyanya kuoma. Chengetedza tembiricha kubva pasi pechitoro pa20–25°C uye hunyoro pa50–60%. Shandisa zvinhu zvinobvisa hunyoro mumwaka wemvura. Kugadzirisa pasi pevhu (semuenzaniso, kurapwa kwecorona kwemafirimu ePE/PET) kunowedzera kunamira kweinki uye kunoderedza kusashanda zvakanaka kwekuomesa.

Kurapwa kweCorona

Kudzora Hunyoro

Chekupedzisira, hurongwa hwakasimba hwekugadzirisa hunovimbisa kugadzikana kwenguva refu. Gara uchichenesa ma nozzles ekuomesa nezvinhu zvinodziyisa, tarisa kupera kwe anilox roller, uye shandisa zvinhu zvinoyedza dry-tension kuti utarise kunaka kwekudhinda—matanho makuru ekudzivirira matambudziko ane chekuita nekuomesa.

Nguva yekutumira: Chivabvu-29-2025